In 2026, choosing the right extrusion profile is crucial for project success. The market for extruded products is projected to reach 4.5 billion dollars by 2027, showing a steady growth rate. This trend highlights the significance of understanding materials and design options available.

Extrusion profiles play a vital role in various industries, from automotive to construction. Each sector demands specific properties, such as weight, strength, or thermal performance. Selecting the wrong profile can lead to costly delays and redesigns. Industry studies reveal that more than 30% of projects face issues due to inadequate profile selection.

As we explore the best extrusion profile options for your projects, consider both current trends and practical applications. New technologies create innovative profiles with improved functionalities. However, navigating these advancements can be challenging. The best choice often involves trial and error, demanding ongoing evaluation and refinement of your selection process.

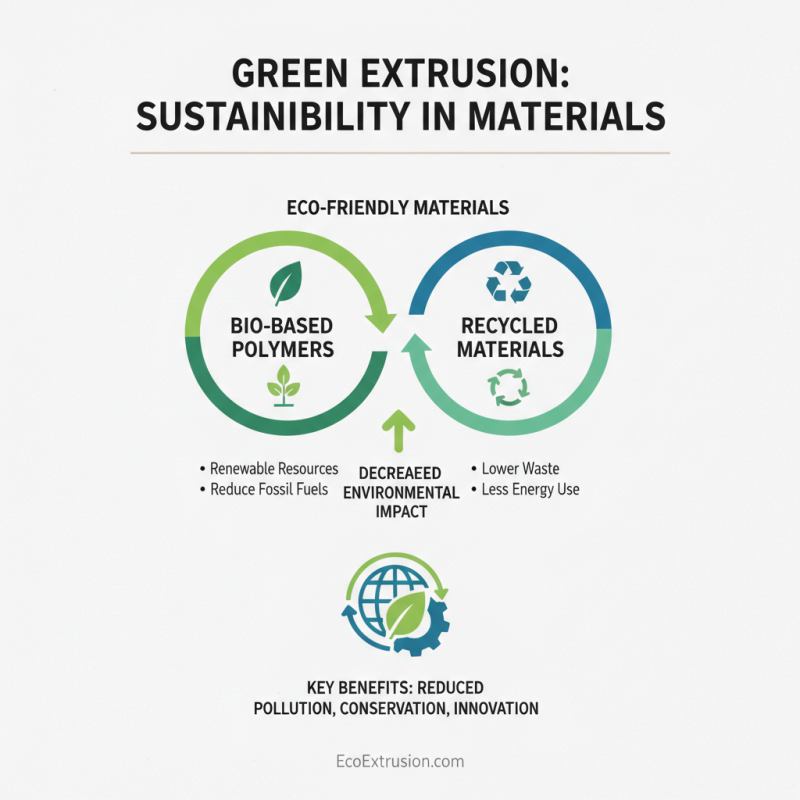

The extrusion profile landscape is evolving rapidly. Various industries are now adopting innovative materials and designs. Sustainability stands out as a key trend. Eco-friendly materials are gaining traction. Extruded profiles made from recycled plastics are becoming more common. They not only save resources but also reduce waste.

In 2026, versatility in design is another notable trend. Although intricate designs are appealing, they often pose manufacturing challenges. Not every project can afford the high costs of complex shapes. Simplicity is sometimes the best route. We might overly focus on aesthetics while ignoring functional considerations. Crafting profiles that work efficiently should take precedence.

New technologies are revolutionizing production methods. 3D printing is entering the extrusion realm. It allows for rapid prototyping and customization. However, this approach may not meet large-scale demand effectively. Striking the right balance between innovation and practicality is crucial. Engaging with these trends can drive your project forward, but it demands careful reflection and planning.

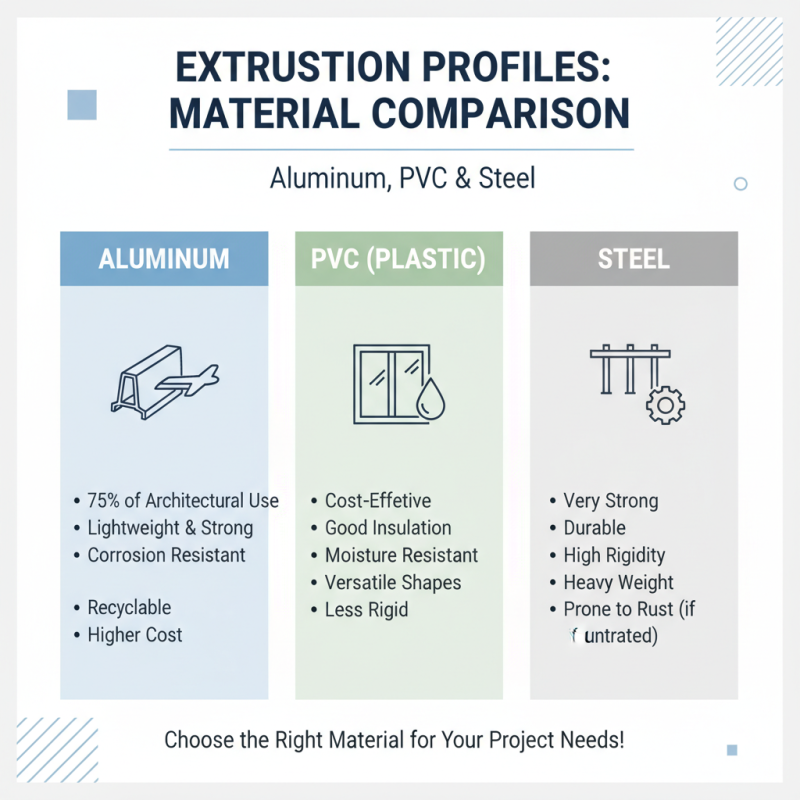

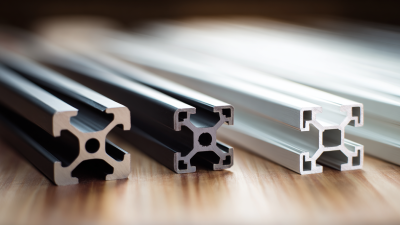

When choosing extrusion profiles, aluminum, PVC, and steel are key materials. Each has its unique advantages and challenges. According to recent industry reports, aluminum is lightweight yet strong, making it a popular choice. It composes about 75% of extrusion usage in architectural applications. However, it can be more expensive than other materials, which is a crucial consideration for budget-sensitive projects.

PVC profiles are another major player in the market. They are resistant to corrosion and can be produced at a lower cost. Around 50% of windows and door frames in the U.S. are made of PVC, highlighting its widespread use. Yet, PVC can be less durable in extreme conditions, raising concerns for long-term viability in certain applications.

Steel profiles are known for their strength and durability. They are commonly used in structural applications. While steel accounts for about 30% of the extrusion market, its weight can be a drawback in applications requiring lighter materials. Balancing these factors is vital for effective project planning. Choosing the right material often involves weighing performance against cost and environmental impact.

In the realm of extrusion profiles, performance is everything. Strength, weight, and durability dictate the success of any project. According to the 2023 Industry Research Report, materials like aluminum and PVC dominate due to their unique balance. Aluminum profiles offer high strength-to-weight ratios, making them ideal for structural applications. They can endure significant mechanical loads while remaining lightweight.

However, durability is often overlooked. A study by the Advanced Materials Institute highlights that while aluminum scores high in strength, it can corrode in harsh environments without proper treatment. PVC, while less strong, offers superior resistance to chemical exposure. This determines its preference in applications where longevity is critical.

Data shows that nearly 30% of projects fail due to poor material selection. It invites reflection on the importance of choosing the right profile. The decision must balance strength with long-term performance metrics. Designers should continuously analyze these factors to ensure quality outcomes. Exploring innovations in composite materials could offer another dimension. Yet, they also come with unknowns, requiring thorough research before integration.

When planning extrusion projects in 2026, budgeting is crucial. Costs can vary dramatically based on material, design, and production volume. Start by analyzing raw material prices. For instance, aluminum and plastic profiles are both popular, yet their costs differ. The choice of material affects not just the budget but also the project's final outcome.

Consider the design process. Complexity often leads to higher costs. A simple design may save money upfront, but it might limit functionality. Balancing cost with quality can be challenging. It's essential to reflect on whether the savings are worth the potential limitations. Additionally, unexpected costs can arise during production. Always allocate a buffer in your budget to accommodate these surprises.

Evaluate supplier options carefully. Some may offer lower prices but require longer lead times. In a tight schedule, this might disrupt your project. Compare quotes and timelines from various suppliers. This strategy may reveal hidden costs. Be prepared to make tough choices. The goal is to achieve a balance between quality and budget while ensuring the project stays on track.

Sustainability is essential in today's extrusion industry. Many projects seek to reduce their environmental impact. Using eco-friendly materials is a vital step. Bio-based polymers offer an excellent alternative. They derive from renewable resources and reduce reliance on fossil fuels. Recycled materials are another good option. They help lower waste and energy use during production.

It's important to think about your project’s lifecycle. Choose materials that are easier to recycle. Many products can be designed to ensure recyclability. This reduces landfill contributions significantly. You might need to adjust your design to support these practices. Flexibility can lead to better sustainability outcomes.

Tip: Always ask your supplier about material sourcing. Ensure that the materials you use are certified and sustainably sourced. Collaborating with partners who prioritize sustainability can enhance your project's impact. Moreover, consider the production process. Adopting energy-efficient practices can also make a difference. Choosing local suppliers can reduce transportation emissions, further benefiting the planet. Don't overlook small changes; they can lead to significant improvements.

We’re here to help and answer your questions.