Automotive manufacturing is undergoing a remarkable transformation. With advancements in technology, the industry is embracing innovative solutions. These innovations are not just about improving efficiency; they also address environmental concerns and consumer demands.

Consider electric vehicles (EVs). They are reshaping the automotive landscape. The shift towards EVs brings both excitement and challenges. Charging infrastructure needs expansion. Battery technology is still developing.

Another area of innovation is automation in production. Robots are becoming common on assembly lines. While leading to faster production, this raises questions about job displacement. Balancing technology with human labor is essential. The future of automotive manufacturing depends on thoughtful integration of these innovations.

In recent years, automation has transformed automotive manufacturing.

Robotics play a crucial role in this evolution. They streamline production lines, increasing efficiency and precision.

Tasks that once required human hands are now handled by machines. This shift allows for faster assembly and higher output.

However, it also raises questions about workforce impact.

Many assembly lines now feature robotic arms capable of performing various tasks. They can weld, paint, and assemble parts with remarkable accuracy.

This reduces the chance of human error, making vehicles safer. Yet, the reliance on robotics leads to fewer jobs in the industry.

Workers must adapt or risk being left behind.

Automation introduces a blend of innovation and challenge. Manufacturers face the temptation to replace workers entirely.

But they must also consider the importance of skilled labor.

Training programs become vital to bridge the gap. As robotics take over repetitive tasks, humans can focus on more complex activities.

This partnership could create a more dynamic work environment. Balancing technology and human input will be essential for the future of automotive manufacturing.

3D printing is transforming prototype development in the automotive industry. This technology enables quick design iterations, shortening the time from concept to prototype. Engineers can produce complex parts faster than traditional methods. It reduces waste and costs, making it a popular choice among manufacturers.

With 3D printing, teams can experiment with innovative designs. However, not all materials are suitable for every project. Certain prototypes may not withstand rigorous testing or production demands. Some designs, while visually appealing, may lack structural integrity. This requires constant evaluation and adjustments.

Collaboration is key in refining these prototypes. Feedback loops from testing help identify weaknesses. Iterative improvements improve overall quality. As teams embrace 3D printing, they face both excitement and challenges. Embracing this technology can lead to groundbreaking developments, but it requires thoughtful consideration of its limitations.

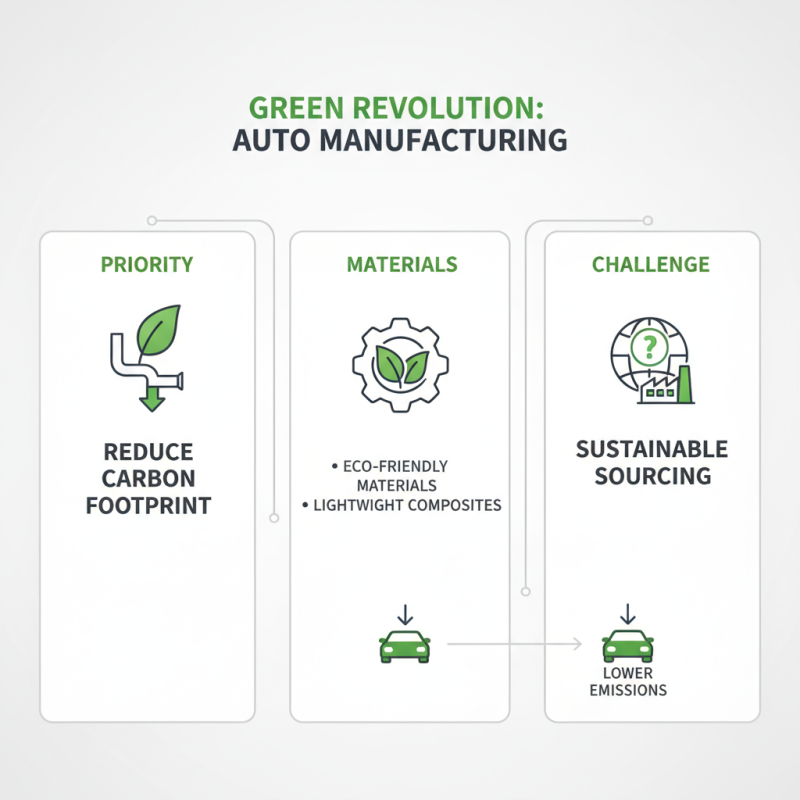

Sustainability has become a driving force in automotive manufacturing. Reducing the carbon footprint is now a priority for many manufacturers. Eco-friendly materials are gaining traction. Lightweight composites help reduce vehicle weight, leading to lower emissions. However, sourcing these materials sustainably can be challenging.

Renewable energy is another focus area. Many facilities are adopting solar and wind power. This shift reduces reliance on fossil fuels. Yet, transitioning to renewable sources requires careful planning. Some factories still struggle to make this change. Energy costs can be a hurdle, impacting overall efficiency.

Innovative manufacturing processes are also being explored. Techniques like 3D printing allow for on-demand production. This can minimize waste significantly. Yet, the technology isn't perfect. It can create challenges in scalability and production speed. Continuous improvement is needed to make these innovations practical for the industry.

The integration of the Internet of Things (IoT) in automotive manufacturing has transformed the industry. IoT enables real-time data collection from vehicles, production lines, and supply chains. This connectivity helps manufacturers streamline processes. A recent report by McKinsey highlights that IoT can improve efficiency by 30%. This efficiency boost can significantly reduce production costs.

However, the thrill of innovation is often tempered by challenges. The reliance on connected systems can introduce vulnerabilities. A study by Deloitte found that 60% of manufacturers are concerned about cybersecurity risks. Ensuring the security of IoT devices is crucial. Hackers can exploit these connections, jeopardizing not just data integrity but also vehicle safety.

Moreover, adopting smart manufacturing requires substantial investment. Companies may face difficulties justifying the costs upfront. Integrating IoT solutions into existing infrastructures often necessitates extensive training. Analyzing data and making informed decisions can be daunting. Bridging the skills gap remains a significant task for many organizations. As tech evolves, so must the workforce. Reflections on these challenges are essential for fostering truly innovative solutions in automotive manufacturing.

AI-driven quality control is transforming automotive manufacturing. This technology enhances production accuracy and safety. By using advanced algorithms, AI examines components meticulously. It identifies defects that human inspectors might miss. This leads to fewer errors and safer vehicles. The technology also reduces waste, improving overall efficiency.

Tips: Consider investing in AI tools. These can streamline your manufacturing processes. Training employees on these systems is crucial. They need to understand how to use AI effectively. Regular updates to the software are necessary. This ensures optimal performance and security.

Despite these advancements, challenges remain. Not all AI systems integrate seamlessly with existing workflows. Some workers may resist change, fearing job loss. It's essential to address these concerns. Open communication can ease transitions. Emphasizing the benefits of AI can help too. AI is not just a tool; it’s a partner in manufacturing.

We’re here to help and answer your questions.