In today's fast-paced economy, machine manufacturing plays a pivotal role in modern industry. According to Dr. Emily Carter, a renowned expert in this field, “Machine manufacturing is the backbone of innovation and productivity.” This statement underscores the importance of machinery in driving technological advancements and efficiency.

As industries evolve, machine manufacturing must adapt to meet new challenges. For instance, advanced automation is reshaping production lines. However, this transition often leads to workforce concerns and skills gaps. It raises questions about job displacement and the need for retraining initiatives.

Moreover, sustainability remains a key issue in machine manufacturing. Manufacturers are tasked with finding eco-friendly processes. Yet, balancing economic growth and environmental impact continues to be a complex challenge. Thus, the conversation around machine manufacturing must also explore these intricacies.

Machine manufacturing plays a crucial role in modern industry. In 2022, the global machine manufacturing market was valued at approximately $2 trillion. This significant figure illustrates the industry's importance in supporting various sectors, including automotive, aerospace, and construction. The expansion of automation continues to push demand for advanced machinery. It is estimated that by 2025, the automation market will reach $300 billion.

The integration of advanced machinery helps improve efficiency and reduce costs. For instance, CNC (Computer Numerical Control) machines enhance precision, reducing waste material. This precision can lead to a reported increase in productivity by up to 50%. However, not all companies adopt these technologies. Some smaller manufacturers struggle due to initial costs. They may miss out on the benefits of innovation.

Research indicates that nearly 70% of manufacturers are investing in technology upgrades. Yet, a substantial number remain hesitant. This hesitation may hinder their competitiveness in the global market. Addressing skill gaps is also a concern. Many workers lack the expertise to operate advanced machinery effectively. Overall, machine manufacturing is essential but not without challenges.

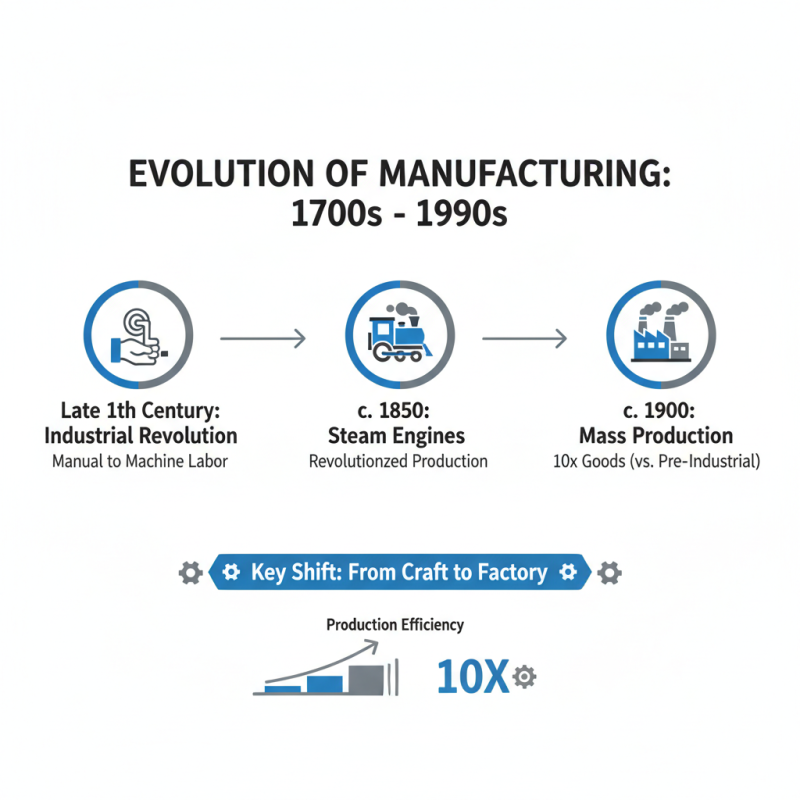

The historical development of machine manufacturing techniques is fascinating. It began during the Industrial Revolution in the late 18th century. This era marked a significant shift from manual labor to machine-based production. By 1850, steam engines had revolutionized industries, increasing production efficiency. Reports indicate that by 1900, manufacturers could produce 10 times more goods compared to the pre-Industrial era.

In the 20th century, machine tools evolved rapidly. The introduction of CNC (computer numerical control) technology in the 1950s further transformed manufacturing practices. CNC machines allowed for precision machining, reducing errors significantly. However, while these advancements boosted productivity, they also created challenges. Many workers faced skill gaps. As machines took over, the demand for manual skills decreased. Today, around 20% of workers find it difficult to keep pace with new technologies.

Contemporary methods continue to evolve. The advent of additive manufacturing and automation has opened new doors. Yet, it raises questions about sustainability and ethical practices in production. Some reports suggest that the environmental impact of machine manufacturing is still a concern. Balancing innovation with responsibility is crucial for future development. Industry experts urge a focus on eco-friendly techniques to ensure longevity in manufacturing.

Machine manufacturing plays a critical role in today's industrial landscape. Its applications span a wide range of sectors. In the automotive industry, precise machine parts enhance vehicle safety and performance. These components must be made with high accuracy, which is often challenging. Additionally, even small errors can lead to significant issues.

The aerospace sector relies heavily on advanced manufacturing techniques. Aircraft parts require high durability and lightweight materials. However, achieving this balance is not always straightforward. Even minor defects can compromise safety. In medical technology, machine manufacturing aids in creating precise instruments and implants. These devices greatly improve patient outcomes, but the process isn't flawless.

The production of consumer electronics also depends on sophisticated machinery. Here, the pace of innovation is rapid. Yet, quality control remains an ongoing challenge. Each batch must meet strict standards. Variability can impact both performance and consumer trust. These examples highlight the importance of robust manufacturing processes while also revealing areas for improvement in quality assurance.

Machine manufacturing plays a vital role in driving economic growth and enhancing productivity. It provides the backbone for various industries. Factories equipped with advanced machinery can produce higher volumes of goods at a lower cost. This efficiency leads to increased output and better profit margins. The use of machines reduces human error, resulting in improved product quality.

Moreover, it creates jobs in various sectors. While automation may eliminate some positions, it also generates new opportunities in machine maintenance and programming. There is often a skills gap. Many workers need training to handle modern machinery effectively. This can slow down the transition to more automated processes.

The benefits of machine manufacturing extend beyond individual companies. It stimulates supply chains and boosts competitiveness in the global market. However, industries must be cautious. Rapid automation might outpace workforce readiness. Continuous investment in education and training is essential. Balancing technology use with human skills is crucial for sustainable economic development.

| Dimension | Description | Impact on Economic Growth (%) | Productivity Increase per Year (%) |

|---|---|---|---|

| Automation | Integration of automated machinery to enhance efficiency. | 3.5% | 20% |

| Quality Control | Machine manufacturing improves product quality through precision. | 2.0% | 15% |

| Job Creation | Increases demand for skilled labor and technical jobs. | 1.8% | 10% |

| Innovation | Encourages the development of new technologies and processes. | 4.2% | 25% |

| Supply Chain Efficiency | Enhances logistics and inventory management systems. | 2.5% | 18% |

Machine manufacturing is evolving rapidly. Advanced technologies are reshaping the industry, driving efficiency and precision. Automation plays a key role in this transformation. Robots now handle tasks that humans performed before. This shift minimizes errors and boosts productivity. However, it’s vital to address the potential impact on the workforce. Job displacement remains a concern as machines take on more roles.

Digital manufacturing is gaining traction. Techniques like 3D printing allow for quick prototyping and customization. This method reduces waste and lowers production costs. Yet, companies must invest in training programs to adapt their teams. A gap in skills could hinder the progression of these innovations. Additionally, incorporating artificial intelligence into machine manufacturing optimizes processes. AI analyzes data quickly, providing insights for better decision-making.

The future is bright but complex. Sustainability is another essential aspect. Manufacturers face pressure to reduce their environmental footprint. This leads to innovative practices and materials that are eco-friendly. Companies must balance technological advancements with responsible practices. Reflecting on these changes is crucial for navigating the ever-evolving landscape of machine manufacturing.

We’re here to help and answer your questions.