Introduction

Aluminium’s inherent qualities-such as lightweight strength, excellent thermal and electrical conductivity, corrosion resistance, and cost-effectiveness-make it an indispensable material for building robust systems. These characteristics not only ensure safety and longevity but also help in reducing overall production and operational costs. With industries constantly striving for higher performance and sustainability, aluminium stands out as the ideal solution.

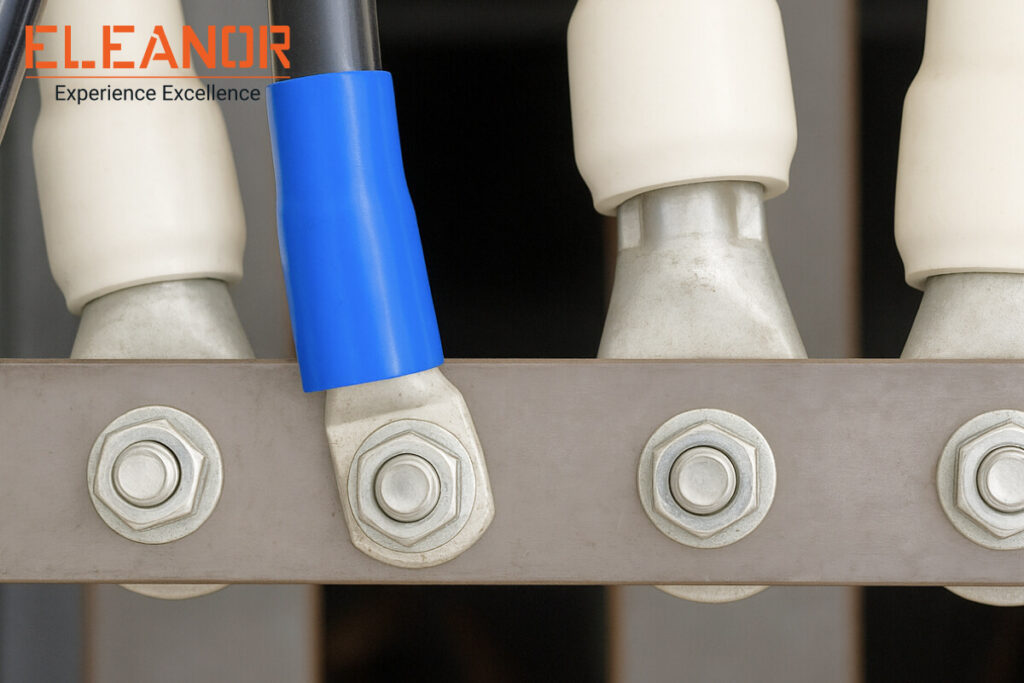

The use of aluminium tubes for control panels & lugs manufacturing has been growing steadily due to their adaptability to different environments and applications. Control panels, being the nerve center of industrial operations, require components that guarantee reliability and precision. Aluminium’s superior conductivity and ease of fabrication allow manufacturers to design tubes that meet the demanding needs of power transmission and distribution systems. Similarly, in lugs manufacturing, aluminium’s compatibility with copper and its ability to withstand high mechanical stress make it a go-to choice for creating secure, long-lasting electrical connections.

Furthermore, aluminium tubes offer a sustainable advantage. As industries move toward eco-friendly practices, the recyclability of aluminium reduces environmental impact without compromising performance. This aligns with global trends toward green manufacturing and sustainable infrastructure development.

In this article, we will explore the reasons behind the growing popularity of aluminium tubes for control panels & lugs manufacturing, their advantages over traditional materials, and how they are redefining efficiency in industrial applications. From performance benefits to sustainability, aluminium continues to shape the future of modern industries.

Understanding Aluminium Tubes in Industrial Applications

Aluminium tubes are hollow, lightweight yet strong components manufactured through precision extrusion processes. Their high conductivity, corrosion resistance, and machinability make them indispensable across electrical and mechanical industries. In particular, aluminium tubes for control panels & lugs manufacturing play a crucial role in ensuring seamless current flow, safe connections, and reliable system performance.

As one of the most versatile extruded forms, aluminium tubes balance durability with design flexibility, enabling industries to integrate them into advanced systems where efficiency and longevity are essential. Leading aluminium extrusion manufacturers in India continuously innovate these products to meet the growing demand for customized solutions in electrical and industrial sectors.

Common Uses in Electrical, Mechanical, and Industrial Systems

The use of aluminium tubes spans across multiple domains thanks to their unique properties:

1. Electrical Applications

- Widely used in control panels and lugs due to excellent conductivity.

- Provide strong yet lightweight pathways for electrical wiring and connections.

- Support efficient grounding and current distribution in complex systems.

2. Mechanical Applications

- Integral in frameworks, piping, and enclosures where corrosion resistance is critical.

- Their formability allows easy integration into precision equipment.

3. Industrial Systems

- Extensively used in textile machinery, pumps, and pneumatic applications.

- Aluminium lugs manufacturers in India rely on high-grade aluminium tubes to produce lugs that meet stringent safety and performance standards.

- Aid in building reliable industrial control systems where consistency and safety cannot be compromised.

By leveraging the expertise of trusted aluminium extrusion manufacturers in India, industries gain access to high-performance tubes tailored to electrical and mechanical needs. Their role in control panels and lug manufacturing makes them a preferred choice for modern infrastructure, energy systems, and automation solutions.

Also Read: From Solar to Smart Grids: Aluminium in Power and Energy Applications

How Aluminium is the Preferred Choice Control Panels & Lugs Manufacturing

In modern electrical systems, efficiency, safety, and durability are non-negotiable. This is why aluminium has emerged as the material of choice for control panels and lugs manufacturing. With growing demand for reliable and cost-effective solutions, industries are turning towards aluminium tubes for control panels & lugs manufacturing due to their excellent balance of strength, conductivity, and performance. From aluminium tube sections to custom extrusions, the material ensures both functional reliability and long-term sustainability. Supported by innovations from the top aluminium extrusion companies in India and trusted aluminium lugs manufacturers in India, aluminium has set new benchmarks in electrical infrastructure.

1. Lightweight with High Strength

One of the key advantages of aluminium tubes is their exceptional strength-to-weight ratio. Unlike heavier metals, aluminium combines durability with ease of handling, making it ideal for complex assemblies in control panels and lug systems. Aluminium tube sections provide robust support without adding unnecessary bulk, ensuring equipment is not only reliable but also easier to install and maintain. For industries prioritizing high performance with efficient logistics, this makes aluminium a winning choice.

2. Excellent Electrical Conductivity

Electrical applications demand materials that offer seamless conductivity. Aluminium meets this requirement while being lighter and more cost-efficient than copper. Aluminium tubes for control panels & lugs manufacturing ensure smooth electrical flow, reducing energy loss and optimizing performance in high-demand applications. This makes it a trusted solution widely adopted by aluminium lugs manufacturers in India for ensuring dependable connections in power systems.

3. Corrosion Resistance

Industrial environments can often be harsh, exposing materials to moisture, chemicals, and extreme temperatures. Aluminium tube sections offer natural corrosion resistance, extending the life of control panels and lugs even under challenging conditions. This durability ensures reduced maintenance costs and fewer replacements, making aluminium the go-to option for manufacturers aiming to meet long-term sustainability and safety requirements.

4. Cost-Effectiveness

Beyond performance, cost efficiency is another major reason why industries prefer aluminium. Compared to copper, aluminium is significantly more affordable while still meeting essential performance standards. By choosing aluminium tubes for control panels & lugs manufacturing, businesses gain access to reliable solutions without overshooting budgets. With top aluminium extrusion companies in India producing high-quality profiles and aluminium lugs manufacturers in India delivering precise components, industries benefit from a balance of performance, longevity, and cost savings.

Aluminium Tubes in Control Panels

Aluminium has become the go-to material for modern electrical applications, especially in control panels and lugs manufacturing. The versatility, strength, and cost-effectiveness of aluminium tubes for control panels & lugs manufacturing make them indispensable in power distribution systems and automation industries. Beyond affordability, aluminium tubes also offer design flexibility that supports safe, efficient, and high-performance electrical systems.

Role in Safe and Efficient Wiring

- Excellent conductivity: Aluminium tubes ensure smooth electrical flow, reducing energy loss and improving wiring efficiency.

- Lightweight durability: Their strength-to-weight ratio makes them a safer and more manageable choice compared to alternatives.

- Corrosion resistance: Aluminium tube sections enhance longevity, especially in humid or high-temperature environments.

- Safety assurance: Proper use of aluminium tubes in control panels reduces risks of overheating and short circuits, ensuring compliance with industrial safety standards.

Heat Dissipation and Space Optimization

- Superior thermal management: Aluminium’s natural ability to dissipate heat prevents equipment failures caused by overheating.

- Compact installations: Aluminium tubes allow for efficient space utilization, enabling more streamlined and organized control panel layouts.

- Performance stability: Their role in maintaining optimal temperatures contributes to longer equipment lifespan.

Case Examples of Usage in Power Distribution Systems

- Industrial control panels: Widely used in automation industries where space optimization and reliability are key.

- Power lugs and connectors: Aluminium tubes for control panels & lugs manufacturing provide secure connections for heavy-duty electrical loads.

- Automotive and aerospace sectors: The rising use of aluminium tubes in automotive & aerospace highlights their adaptability, combining lightweight properties with robust performance.

- Renewable energy systems: Incorporated into solar and wind power installations for safe energy transmission.

Also Read: Glazing & Facade Systems: Merging Aesthetics with Structural Strength

Aluminium Tubes in Lugs Manufacturing

The demand for efficient and reliable electrical systems has placed aluminium as a material of choice for modern industries. Among its many applications, aluminium tubes for control panels & lugs manufacturing have emerged as a key solution for energy and power distribution. Lightweight, corrosion-resistant, and cost-effective, aluminium tubes are shaping new standards for electrical connections while supporting sustainability goals. With Indian aluminium extrusion manufacturers in global markets driving innovation, these products are becoming a trusted component worldwide.

Importance of Aluminium Lugs in Energy Systems

Aluminium lugs play a critical role in ensuring safe and efficient energy transfer. They act as connectors between cables and control panels, reducing energy losses and ensuring uninterrupted power flow. The use of aluminium tubes in lug production enhances conductivity while keeping the system lightweight, which is essential in large-scale energy and industrial applications. Furthermore, their compatibility with different conductor materials makes them a versatile solution across industries.

Precision Forming and Secure Electrical Connections

One of the major advantages of aluminium tubes for control panels & lugs manufacturing is their precision forming ability. Manufacturers can extrude aluminium tubes into exact specifications, ensuring consistent dimensions and performance. This precision allows for stronger and more secure crimping during lug assembly, resulting in reliable electrical connections. Additionally, the smooth surface finish of aluminium tubes reduces resistance and heat buildup, enhancing overall system safety.

Durability and Reliability Benefits

In high-demand electrical environments, durability is non-negotiable. Aluminium tubes used for lugs offer excellent resistance to corrosion, oxidation, and environmental stress, ensuring long-lasting performance even in challenging conditions. Their lightweight nature also eases installation without compromising strength. With the backing of leading Indian aluminium extrusion manufacturers in global markets, industries can trust aluminium lugs and control panel components to deliver reliability, cost savings, and energy efficiency.

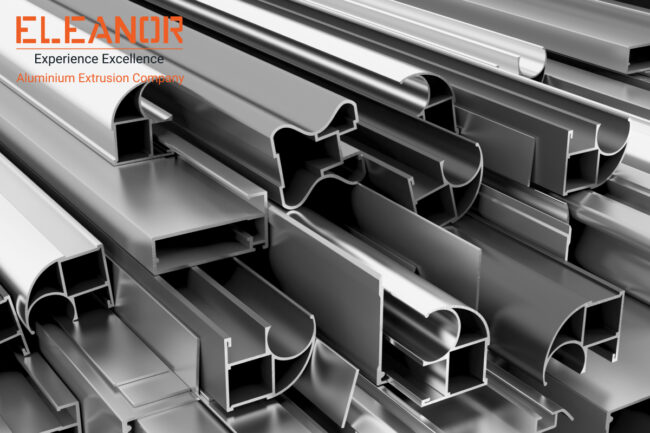

Manufacturing Insights For Aluminium Tubes

In modern electrical and industrial setups, the demand for reliable, durable, and high-performance materials has grown significantly. Among these, aluminium tubes for control panels & lugs manufacturing have become the preferred choice for industries. Known for their lightweight strength, corrosion resistance, and excellent conductivity, aluminium tubes outperform many traditional materials. Their versatility across aluminium extrusion profiles allows manufacturers to customize shapes and sizes, meeting specific requirements for power, control, and connectivity.

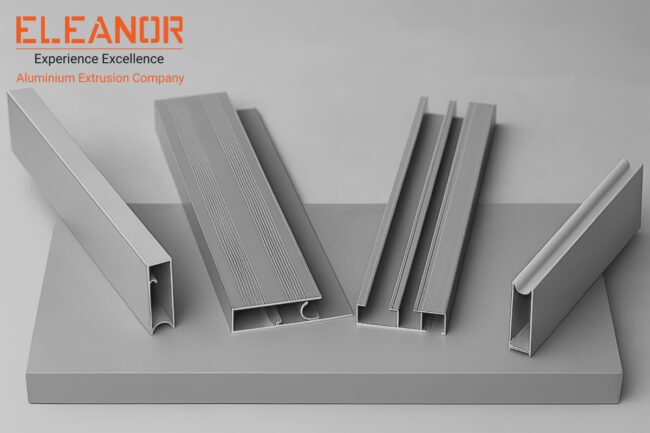

Types of Aluminium Extrusion Profiles for Tubes

Aluminium extrusion offers a wide variety of profile options to suit different industrial applications. For control panels and lug manufacturing, the following aluminium extrusion profile types are commonly used:

- Round Aluminium Tubes: Ideal for wiring, cable management, and structural support in control panels.

- Square and Rectangular Tubes: Provide strong load-bearing capacity and compact design for electrical housing.

- Seamless Tubes: Perfect for high-precision applications, ensuring durability and uniform conductivity.

- Custom Tubes: Tailored as per client specifications for specialized panels and connector systems.

Compared to other types of aluminium bars, tubes offer greater design flexibility and surface finishing options, making them indispensable in power and electrical component production.

Process of Extrusion and Quality Standards

The manufacturing of aluminium tubes for control panels & lugs manufacturing involves a highly controlled extrusion process. Using top-grade billets, the aluminium is heated and pushed through a die to create hollow sections with consistent dimensions. Key quality standards followed by leading aluminium extrusion manufacturers in India include:

- Dimensional Accuracy: Ensuring precise thickness and diameter for seamless integration.

- Mechanical Strength: Achieving optimal tensile strength for durability in industrial environments.

- Surface Treatment: Applying anodizing or powder coating for corrosion resistance.

- Electrical Conductivity Testing: Maintaining superior performance in power transmission and connectivity.

These quality checks guarantee that aluminium tubes meet both global standards and the rigorous demands of industries that rely on control panels and lug manufacturing.

Also Read: Architectural Standard Sections: Building Blocks of Modern Design

Control Panels & Lugs Manufacturing Applications Across Industries

1. Power & Energy Sector

- Aluminium tubes play a vital role in switchgear, transformers, and control panels due to excellent electrical conductivity.

- Industries prefer them over copper for cost savings without compromising performance.

- Aluminium lugs manufacturers in India supply robust connections for energy distribution networks.

2. Automotive & Transportation

- Lightweight aluminium tubes improve fuel efficiency while maintaining high strength.

- Widely used in electrical harnesses, wiring systems, and control panels of vehicles.

- Automotive OEMs source from aluminium extrusion manufacturers in India to meet global quality standards.

3. Industrial Machinery & Equipment

- Aluminium tubes for control panels & lugs manufacturing are crucial in heavy machinery, ensuring reliable electrical performance.

- Their corrosion resistance supports long service life in harsh industrial environments.

4. Construction & Infrastructure

- Buildings and smart infrastructure projects rely on aluminium tubes in control systems and wiring applications.

- Fire-safe and durable, they meet modern construction demands.

5. Electronics & Renewable Energy

- Electronics manufacturers use aluminium tubes in compact control panels and energy storage systems.

- In renewable energy projects, aluminium lugs manufacturers in India provide essential components for solar, wind, and EV infrastructure.

Redefine Control Panel Performance with Premium Aluminium Tubes Today!

In today’s competitive industrial landscape, efficiency, durability, and reliability are non-negotiable. That’s why aluminium tubes for control panels & lugs manufacturing are increasingly becoming the first choice for forward-thinking industries. Their lightweight strength, superior conductivity, and corrosion resistance not only ensure long-lasting performance but also streamline production and reduce maintenance costs.

As demand continues to grow, sourcing from the right partner becomes critical. Choosing an extruded aluminium products manufacturer in India ensures you get globally competitive quality with the advantage of local expertise and cost-efficiency. By embracing aluminium solutions, industries can redefine control panel performance, enhance safety, and power innovation for the future.