Introduction

This blog is crafted to help engineers, designers, and buyers make smart decisions when selecting custom aluminium profiles for hardware. Whether you’re sourcing from an aluminium extrusion company, a trusted extruded aluminium products manufacturer in Gujarat, or a leading extruded aluminium products manufacturer in India, understanding your options is the first step to long-term performance.

What Are Hardware Profiles?

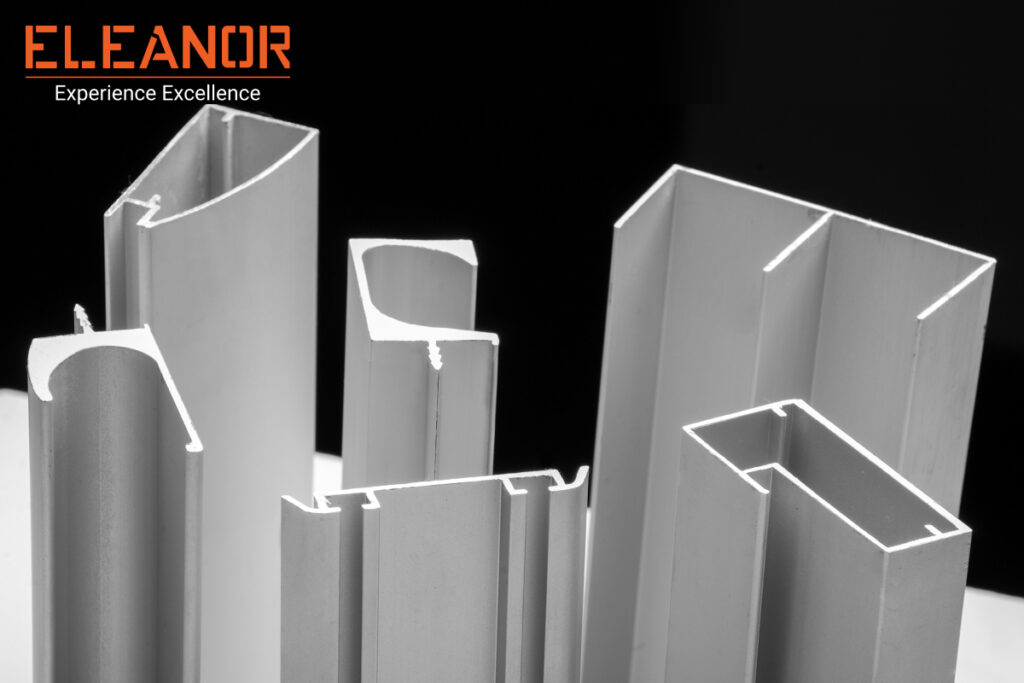

Aluminium hardware profiles refer to a specialized category of aluminium extrusions specifically designed for use in functional and decorative hardware applications. Unlike structural or framing profiles that primarily support load-bearing structures, hardware profiles are tailored to serve precise mechanical or operational functions within a system.

Common examples of hardware profiles include hinges for movement, handles for access, tracks for sliding systems, and brackets or locking mechanisms for secure assembly. These profiles are crucial in a wide range of applications, be it in machinery, control panels, enclosures, doors, windows, or modular industrial equipment.

What sets hardware profiles apart is their need for exact dimensional accuracy, smooth finishes, and compatibility with other components. They often undergo specialized machining, surface treatments, and custom design to suit unique operational environments.

For projects that demand superior fit and performance, custom aluminium profiles for hardware provide the ideal solution. These profiles can be engineered to meet specific design and functional requirements, ensuring seamless integration and long-lasting durability.

As industries evolve, the demand for high-performance, application-specific hardware profiles continues to grow, making them an indispensable choice for modern manufacturing and design.

Categories of Aluminium Hardware Profiles

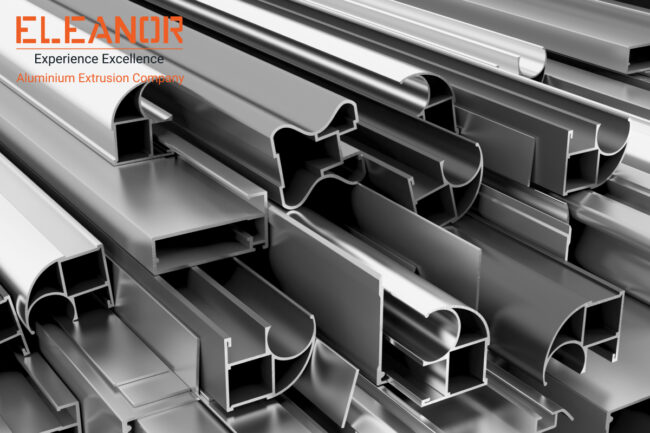

Hardware profiles come in a wide range of designs, each serving a specific role in the performance and aesthetics of equipment, enclosures, and architectural systems. Understanding the various categories helps you select the right aluminium extrusion profile for your application.

1. Functional Hardware Profiles

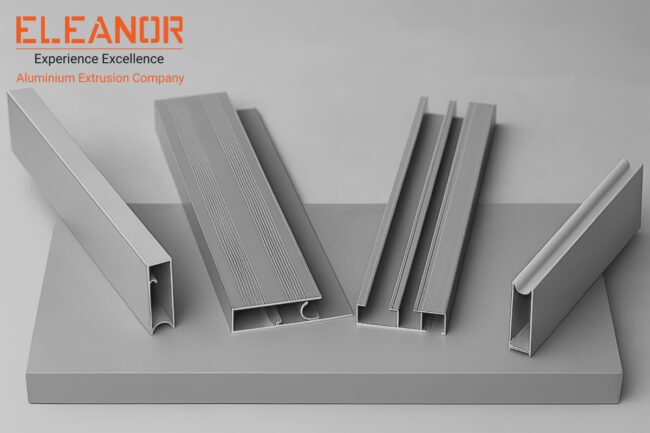

These profiles are designed to perform specific mechanical or operational tasks. Common examples include sliding tracks for doors and panels, locking channels used in enclosures, and cable management profiles for routing and protecting wires. These components are essential for smooth operation, safety, and accessibility in machines and modular systems.

2. Decorative Hardware Profiles

Used to enhance visual appeal without compromising durability, decorative profiles include edge trims, frame covers, and other architectural elements. They add a refined finish to doors, partitions, and furniture while also offering protection against wear and impact. These profiles combine functionality with aesthetics, making them ideal for interior and architectural applications.

Explore more: Types of Architectural & Construction Profiles for Every Structure

3. Assembly Hardware Profiles

These are the connectors and joiners that bring systems together. Brackets, hinges, and joining profiles fall into this category. They ensure structural integrity and simplify the assembly of modular systems, making installation and maintenance more efficient.

4. Custom Engineered Profiles

When off-the-shelf options don’t meet performance or design needs, custom aluminium profiles for hardware are the solution. Tailored to fit specific machines, devices, or architectural projects, these profiles offer exact compatibility, optimized performance, and streamlined integration, especially when developed by an experienced aluminium extrusion company or extruded aluminium products manufacturer in India.

Each of these categories plays a vital role in building strong, functional, and visually appealing systems across industries.

Key Considerations When Selecting Aluminium Hardware Profile

Choosing the right aluminium hardware profiles requires a detailed understanding of the application’s functional and environmental demands. Here are the key factors to consider:

1. Application Requirements

The intended function of the hardware profile should guide your selection. For example, applications involving movement, like sliding or pivoting mechanisms, require profiles with excellent mechanical strength and wear resistance. Profiles used in load-bearing or high-friction areas must be durable and engineered to withstand continuous stress.

2. Fit and Compatibility

Profiles should integrate seamlessly with other components, extrusions, or assemblies. A poor fit can lead to assembly issues or reduce the lifespan of the equipment. Always check compatibility with hinges, locks, and fasteners in advance.

3. Profile Dimensions and Tolerances

Precision is critical. Even a minor deviation can affect the efficiency and safety of the hardware system. Accurate measurements ensure a secure, rattle-free fit and support long-term functionality.

4. Surface Treatment

Surface finishes such as anodizing, powder coating, or brushing improve both aesthetics and durability. These treatments help resist corrosion, wear, and environmental damage, especially in outdoor or industrial settings.

5. Environmental Conditions

Profiles exposed to moisture, high temperatures, chemicals, or abrasive environments must be specially treated and made from the right aluminium alloy to ensure performance and longevity.

Industry-Specific Examples

-

Machine Manufacturing

Custom aluminium profiles for hardware are widely used in machinery, for protective covers, cable tracks, sensor mounts, and operator panels. These profiles enhance equipment reliability while offering easy access for maintenance.

-

Architectural Hardware

In doors, windows, and partitions, aluminium profiles are shaped into sliding tracks, edge trims, and ergonomic handles. Their sleek design, strength, and weather resistance make them ideal for architectural use.

-

Furniture and Interiors

Furniture systems benefit from aluminium trims, pull handles, and adjustable framing components. These not only offer visual appeal but also flexibility in design and layout.

-

Electronics and Automation

From mounting rails for circuit boards to enclosures for control panels, aluminium hardware profiles provide lightweight, EMI-resistant, and customizable solutions that ensure smooth operation and protection of sensitive components. The rise of automation is reshaping extrusion manufacturing by streamlining operations, enhancing consistency, and lowering operational costs.

Choosing the right profile, based on these factors and industry needs, is essential for ensuring both functionality and product integrity.

Eleanor Aluminium’s Expertise in Hardware Profiles

At Eleanor Aluminium, we specialize in delivering precision-engineered aluminium hardware profiles tailored to meet diverse industrial needs. As a trusted aluminium extrusion company, we offer both standard and custom aluminium profiles for hardware, ensuring perfect fit, strength, and functionality across a wide range of applications.

Our in-house engineering team provides expert assistance in prototyping, profile selection, and design optimization, helping clients turn concepts into high-performance extrusions. Whether it’s for sliding systems, handles, brackets, or decorative trims, our advanced extrusion technology enables us to meet exact specifications with tight tolerances.

As a leading and top aluminium extrusion manufacturer in India, and a reputable extruded aluminium products manufacturer in Gujarat, we prioritize quality at every stage. From alloy selection and surface finishing to final inspection, our strict quality control processes ensure each hardware profile performs reliably in its intended environment. We also offer a range of surface treatments like anodizing and powder coating for enhanced durability and aesthetic appeal.

Conclusion

Choosing the right aluminium hardware profile is essential for ensuring strength, compatibility, and long-term performance. We encourage designers, engineers, and manufacturers to carefully evaluate their project requirements and work with experts who understand the intricacies of hardware applications.

Contact Eleanor Aluminium Industries for expert guidance and high-performance solutions in custom aluminium profiles for hardware that elevate your product’s quality and reliability.